UAE: english

UAE: english International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishV&A Museum 'Visual & Durable Concrete'

Achieving Visual & Durable Concrete, through the use of Zemdrain® Controlled Permeability Formwork Liner on the V&A Project, Dundee.

The New Waterfront Development

As part of Dundee’s Waterfront £1 billion redevelopment, The Victoria & Albert Museum opted to construct a new iconic structure to display the brilliance of Scottish creativity. The structure will be at the forefront of Dundee’s transformation and, according to forecasts, the redevelopment will attract over 350,000 international visitors per year to East Scotland – firmly placing Dundee on the map!

Why build the V&A, Dundee?

- To generate new energy, pride and sense of purpose.

- To attract new business, investors and professionals.

- To construct an exciting new visitor destination.

This inspirational building has been designed to a high environmental specification and has a recognised measure of sustainability.

Structure Characteristics and Challenges

V&A – 'A living room for the city'

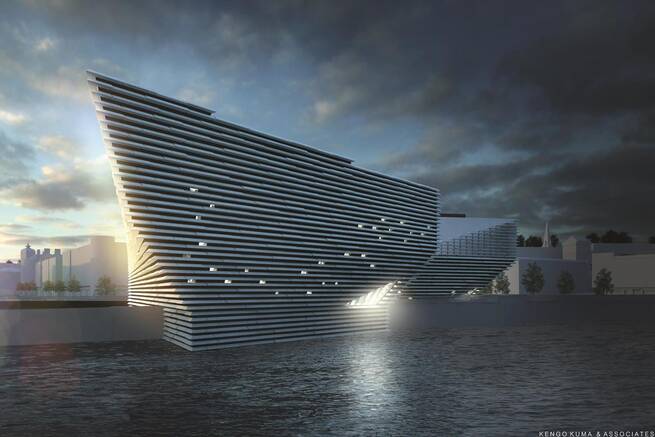

The V&A project is the 1st British building to be designed and built by the Japanese architectural practice. Kengo Kuma’s vision was to provide a welcoming space for visitors to enjoy and socialise, thus providing a way of reconnecting the city of Dundee to its historic River Tay Waterfront. Thanks to the architectural team, the extraordinary building is a testament to great design and innovation.

'Scottish Cliff Face' appearance

Every building defines its own place within its environment – and the V&A Museum is no exception. This massive three-story concrete structure, which boasts over 8,000m2 of floor area and 11,000m2 of external concrete façade, is to resemble a natural Scottish cliff face, with dark granite textures, crevices and overhangs. The structure consists of 21 separate external wall sections, with no straight external walls.

To achieve such characteristics, the architect developed a concrete specification, developed to mirror the local Scottish rock:

- A very dark, almost black pigmented concrete colour.

- A consistent, matt, high quality finish.

To complete the illusion of a Scottish cliff face, the majority of the concrete surface was later covered by precast rough stone cladding units, each panel weighing in excess of 3 tons, once completed.

Environmental attack

Due to its close proximity to the Firth of Tay, and the threat of attack from sea water, chlorides and sulphates, the new concrete façade is exposed to:

- Chloride and chemical attack.

- Pre-longed exposure to freeze-thaw, from local climatic conditions.

These conditions posed initial concerns to the design team concerning the building’s design life.

Product Specification: Design and Construction Team

Zemdrain® CPF liner, supplied by MAX FRANK, was used on this prestigious project for various reasons. The members of the design team discovered various benefits in its use – considering both concrete durability and aesthetics:

The Architect led the design team in creating a building which would represent Scotland. One of the top priorities was the concrete quality and colour; a dark pigmented colour, with a high quality, regular concrete surface finish, was specified.

The Engineer had been impressed by the concrete finish on the Queensferry Crossing (formerly known as the Forth Replacement Crossing) where Zemdrain® CPF liner was used to achieve a dark, consistent concrete finish. Arup suggested the use of Zemdrain® CPF liner to the Architect, for the V&A project.

The Main Contractor also appreciated the benefits of using Zemdrain® CPF liner from the Queensferry Crossing project. Owing to the additional durability benefits which Zemdrain® CPF liner offers to the concrete, BAM decided to use it on the entire site perimeter sea wall defences.

The Subcontractor had some concerns regarding the concrete finish, in relation to the architectural concrete specification. Many pre-contract trails, mimicking the complexity of the double-curvature formwork and heavy reinforcement congestion, were carried out. These caused most of the concreting issues with excessive honeycombing at the concrete surface. PJ Carey had observed the way in which Zemdrain® eliminated blowholes and honeycombing at the concrete surface on the Queensferry Crossing project.

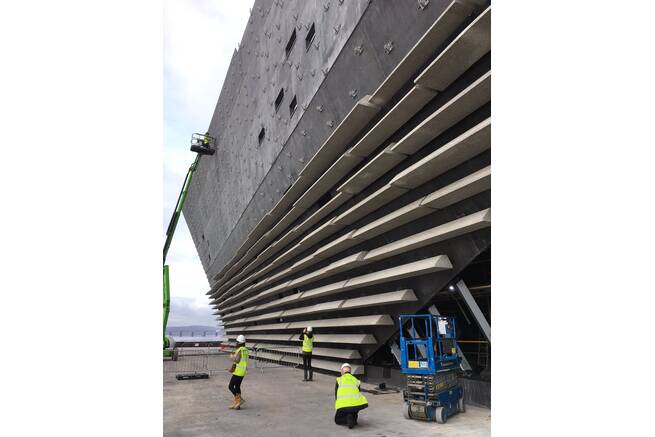

MAX FRANK worked with PJ Carey, together on site, to resolve the challenges ahead:

- MAX FRANK provided on-site technical assistance during the construction of a full size replica trial panel of the most complex wall which helped to develop a specific installation procedure for this project.

- Durability concerns in relation to concrete exposed to the Firth of Tay – and attack from chlorides present in sea water & freeze-thaw. Zemdrain® minimises blowholes & improves early age curing to provide a high quality durable concrete surface with optimum resistance to all forms of environmental attack – and therefore alleviated all of these concerns.

- Lack of concrete space within the heavily reinforced double curving formwork posed threats from blow holes. Zemdrain® CPF liner successfully removed the blow holes.

- PJ Carey realised the benefits of Zemdrain® and how it eliminated blowholes. It was therefore also used on box-out forms and even on internal wall faces, where it was not specified and would never be seen, to prevent honeycombing.

- Due to the double-curvature of many of the walls Zemdrain® MD could not be used because tensioning the liner evenly over the formwork was impossible. MAX FRANK Self-Adhesive liner was used because it does not require tensioning.

- Some of the formwork acted as structural supports and was required to be left in place for approx. 1 year until the building's roof was complete. There were concerns that the Zemdrain® would permanently bond to the concrete, but MAX FRANK provided evidence from previous highway bridge projects that the CPF liner would still peel away after this length of time.

Why CPF Liner from MAX FRANK?

Zemdrain® CPF liner enhances concrete durability by reducing surface porosity and sorptivity, increasing resistance to the concrete in aggressive environments – therefore increasing the life span of the structure and minimising any future maintenance costs through concrete repair solutions.

Zemdrain® - the benefits:

- Achieves a technically enhanced concrete surface.

- Supplies the additional benefits of an aesthetic matt textured finish to all cast concrete surfaces.

- Reduces water/cement ratio at the concrete surface, providing a technically hard concrete surface and an effective increase in concrete cover.

Zemdrain® is available in varying roll widths, suitable for different structural applications, such as bridges, tunnels and water tanks. MAX FRANK supply both re-usable and self-adhesive options.

The V&A scheme was ‘Highly Commended’ at The Concrete Society Awards 2017 - click here.

YouTube Video:

Type of building:

Museum

Clients and Developers:

Dundee City Council

Architect:

Kengo Kuma & Associates

Engineers/ Specialist Planners:

Arup

Building contractor:

BAM

Subcontractor: PJ Carey Civil Engineering

Completion:

2017 (Eröffnung 15.09.2018)

Project link:

Products used

Max Frank Middle East FZE

M3-15, P. O. Box: 123601

Saif Zone, Sharjah

United Arab Emirates