Australia: english

Australia: englishInternational: english International: englishAustralia: english

International: englishAustralia: english Australia: englishAustria: deutsch

Australia: englishAustria: deutsch Austria: deutschCanada: english

Austria: deutschCanada: english Canada: englishCzechia: český

Canada: englishCzechia: český Czechia: českýDenmark: dansk

Czechia: českýDenmark: dansk Denmark: danskFinland: suomi

Denmark: danskFinland: suomi Finland: suomiFrance: français

Finland: suomiFrance: français France: françaisGermany: deutsch

France: françaisGermany: deutsch Germany: deutschHungary: magyar

Germany: deutschHungary: magyar Hungary: magyarItaly: italiano

Hungary: magyarItaly: italiano Italy: italianoNetherlands: nederlands

Italy: italianoNetherlands: nederlands Netherlands: nederlandsNorge: norsk

Netherlands: nederlandsNorge: norsk Norge: norskPoland: polski

Norge: norskPoland: polski Poland: polskiRomania: românesc

Poland: polskiRomania: românesc Romania: românescSlovakia: slovenčina

Romania: românescSlovakia: slovenčina Slovakia: slovenčinaSpain: español

Slovakia: slovenčinaSpain: español Spain: españolSweden: svenska

Spain: españolSweden: svenska Sweden: svenskaSwitzerland: deutsch

Sweden: svenskaSwitzerland: deutsch Switzerland: deutschUAE: english

Switzerland: deutschUAE: english UAE: englishUnited Kingdom: english

UAE: englishUnited Kingdom: english United Kingdom: englishUSA: english

United Kingdom: englishUSA: english USA: english

USA: english

International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Italy: italiano

Italy: italiano Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska Switzerland: deutsch

Switzerland: deutsch UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishHow to: Simple manufacture of expansion joints with complex component cross sections

Whether for force transmission, sealing or special component geometries – there is a great deal of variation in the execution of expansion joints. For that reason, the manufacture of this formwork on the building site is often complex, unreliable and time-consuming.

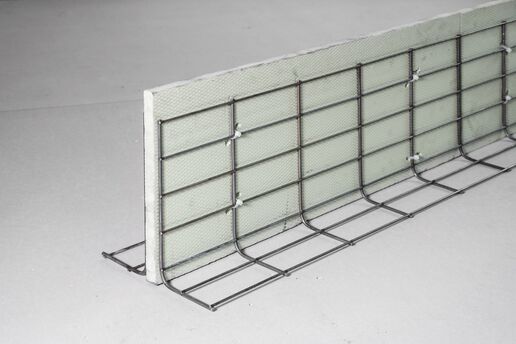

Stremaform® formwork elements for expansion joints are prefabricated according to the project requirements and delivered as a precise fit.

How to:

- Stremaform® formwork elements for expansion joints are planned and manufactured in Germany in accordance with the formwork and reinforcement diagrams.

- All details such as expansion joint insert and rubber water bar cage are already integrated in the factory.

- On the building site the expansion joint elements only need to be positioned and fixed between the existing reinforcement of the concreting sections.

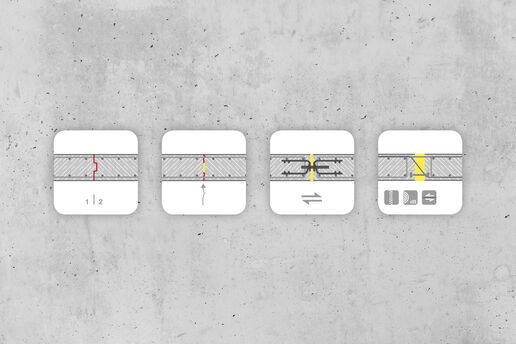

- The expansion joint rubber water bar is inserted into the rubber water bar cage.

- Shear force dowels are inserted into the factory-made recesses if necessary.

- The first and second concreting sections can be concreted simultaneously or successively.

Ask us for individual custom solutions!

Technical advice

+49 9427 189-320

cstmrsrvcmxfrnkcm

We recommend

Contact

Max Frank Pty Ltd

1/42 Balaclava Street

Woolloongabba QLD 4102

Australia