Spain: español

Spain: español International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Italy: italiano

Italy: italiano Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishHow to: Redundant construction cold joint waterproofing using coated metal water stops and injection hose

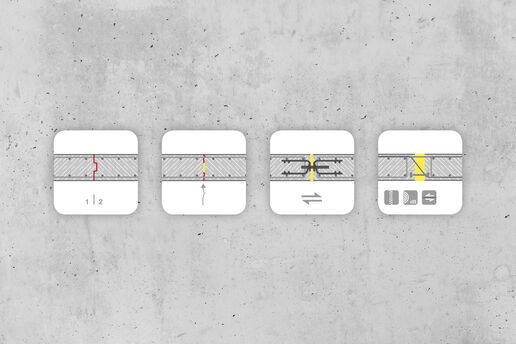

Coated metal water stops have been established to be simple and secure solutions in sealing construction cold joints. After decades of use, these waterstops have proven themselves to be effective, durable and highly reliable. However, in the event of unanticipated joint movement, late shrinkage or ground movement, the primary seal can become compromised and crack injection may be necessary to seal the joint.

The use of a redundant waterproofing system can alleviate this problem. Preferably, an injection hose system for multiple injections is installed in tandem with the coated metal water stop.

How to:

- The slab to rising wall construction cold joint is sealed by installing the Fradiflex® coated metal water stop on the rebar top layer with 30 mm minimum embedment

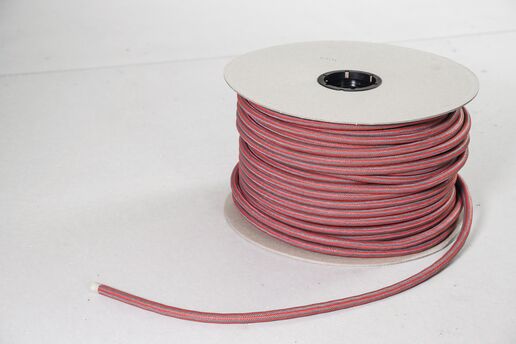

- After concreting the slab the installation of the Intec® injection hose can commence. Ideally, the hose is placed on top the coated metal waterstop on the opposing water bearing side using mounting clips

There are several different options for injection, depending on the selected type of injection hose:

- For polyurethane injections Intec® Premium may be used.

- Where larger voids need to be filled, it is recommended to use the Intec® Cem N hose system, which allows cement pastes and slurries to be injected.

Both systems allow for multiple injections. Intec® Premium can be flushed using compressed air and Intec® Cem N needs to emptied via vacuuming.

Para ello recomendamos

+34 91 826 51 00 - Ext. 212

MAX FRANK España

Calle Agustín de Foxá 40

28036 Madrid

ES Spain