International: english

International: english International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Italy: italiano

Italy: italiano Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishHow to: Optimized concrete surface with use of MAX FRANK CPF liner for tunnel formwork

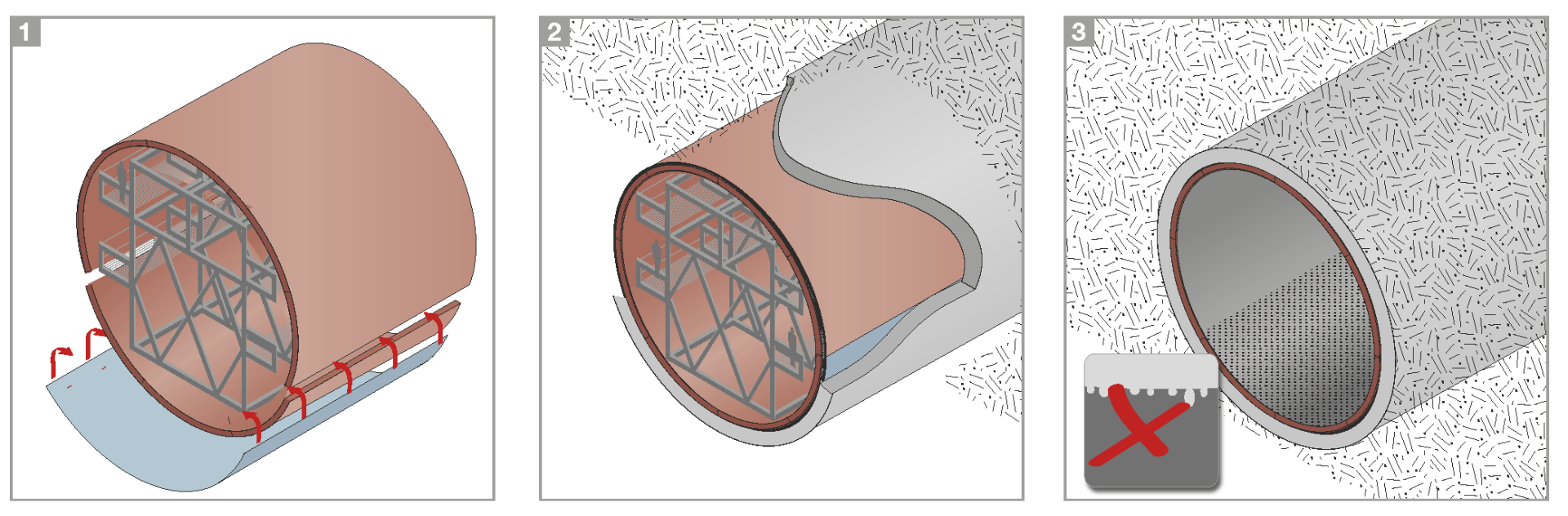

The use of the MAX FRANK controlled permanent formwork liner when concreting tunnel tubes enables an almost void-free, resistible concrete surface.

Water-bearing components e.g. containers and pipes for drinking water, sewage treatment plants or pressure pipes for power plants made of concrete require closed and resistible surfaces to avoid being damaged early.

Especially in horizontal pipes, it is very difficult to create a void-free surface at the bottom of the tube as bubbles accumulate on the formwork.

Through the targeted use of the MAX FRANK CPF liner (controlled permanent formwork), those problems can be solved.

The MAX FRANK CPF liner enables air pockets and excess water to be selectively diverted from the fresh concrete.

After stripping the formwork, the result is a virtually void-free, optimized concrete surface with high resistance against abrasion, hydrolysis and chemical attack.

How to:

- Provide the lower area of the steel formwork in a 50 cm grid with drillings or slots through which the excessive air and cement slurry can escape upwards.

- Clean the steel formwork systematically from contamination, remaining concrete and dust with a combination of formwork oil and brake cleaner and a spatula.

- Remove the protecting foil from the CPF liner and apply it void-free with rubber rollers.

- If there are openings intended for concreting the steel formwork, they must be covered with the foil separately.

- Concrete the lower tunnel tube section through the concreting opening. When vibrating, excessive concrete slurry as well as bubbles can escape through the slots in the steel formwork.

- Concrete the upper tube section.

- Shift the tunnel formwork and re-cover the formwork with the CPF liner after its thorough cleaning if necessary.

We recommend