United Kingdom: english

United Kingdom: english International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Italy: italiano

Italy: italiano Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska Switzerland: deutsch

Switzerland: deutsch UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishHow to: Coffered ceiling with individually shaped displacers

In comparison to conventional reinforced concrete ceilings, coffered ceilings have a considerably reduced dead weight, which minimizes sagging of the ceiling. Due the construction height, the crosswise spanned ribs and the t-beam effect, large spans can be realised with a low concrete consumption.

Apart from the economic efficiency, the special design effect also supports the construction of coffered ceilings. With individually shaped recess formers, not only simple square or rectangular shapes but also visually appealing depressions, which support the architecture of the building, are designed. In addition, unique optical accents can be set using natural or artificial light sources in the coffered ceiling.

How to:

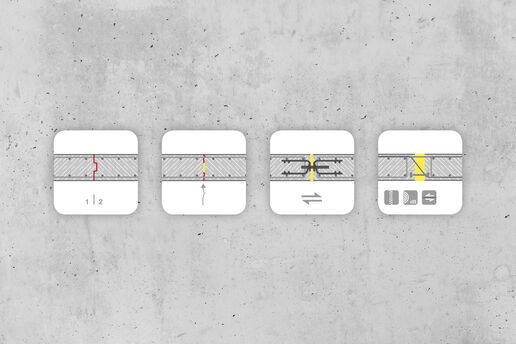

- Provide extensive ceiling formwork and mark the laying grid with a chalk line or rule.

- Fasten individually prefabricated Fratec® formwork bodies to the formwork with double-sided adhesive tape and fasten formwork boards between the formwork bodies – in the area of the later ribs.

- First reinforce the area of the ribs and then install the upper reinforcement observing the concrete cover.

- During concreting, first apply the concrete to the Fratec® displacers in order to enable the weight of the concrete to prevent floating and seeping in behind the hollow bodies.

- Thanks to the conical shape of the Fratec® elements, they can be easily removed after curing of the concrete. The special coating ensures an optimal concrete surface.

May 2018

SERVICE Box

We recommend

+44 1782 598 041

Max Frank Ltd.

Clough Street, Hanley

Stoke-on-Trent, ST1 4AF

Staffordshire

United Kingdom