United Kingdom: english

United Kingdom: english International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Italy: italiano

Italy: italiano Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska Switzerland: deutsch

Switzerland: deutsch UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishShearail® - design above and beyond!

Part 2 of 2: Design Examples

Shearail® punching shear reinforcement is the reliable and cost-effective solution when designing higher load capacities in thinner slabs, for slimmer structures.

This article concludes our previous news story - where we explained that load capacity can be increased and shear loads resisted up to 125% (based on the EC2 limit – as set kmax*= 2.0) ...more details.

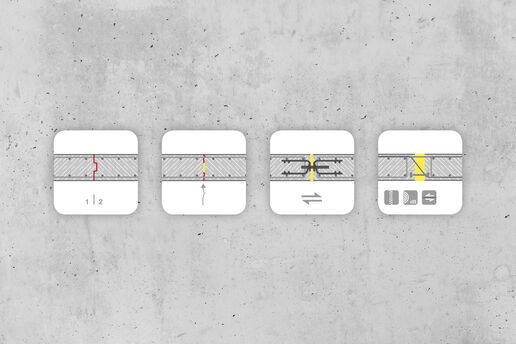

The below design example demonstrates the application of enhanced MAX FRANK Shearail® compared to conventional shear rails. The first part of the example (Section a) reviews the maximum capacity of conventional shear rail products. The second part (Section b) investigates the improvement of the maximum punching shear force using enhanced MAX FRANK Shearail®. Next part (Section c) studies the application of enhanced MAX FRANK Shearail® on the reduction of slab thickness. The last part of the example (Section d) evaluates the application of enhanced MAX FRANK Shearail® on the reduction of column dimensions.

Example - general assumptions:

The punching shear force is calculated for a 6-floor reinforced concrete (RC) building, area of each floor is 550m2, the concrete grade of the structure is C32/40, each floor has 25 columns of 3000mm height.

- Columns: internal condition, ß= 1.15 (less than 25% difference in spans)

- Column size: 300mm x 300mm

- Slabs: slab depth 275mm, concrete cover (top & bottom) 25mm, top and bottom reinforcement B16 @ 200mm (both directions)

Section a) Application of conventional shear rails

Market alternative products - excl. MAX FRANK Shearail®:

For this range of products, the maximum factor that can be achieved by the application of shear reinforcement (kmax) is limited to Kmax vRd,c = 2 vRd,c [NA BS EN 1992-1-1, 6.4.5.(1)].

The calculation (see Appendix 1) shows the maximum design value of the applied shear force (VEd)= 933kN

Section b) Application of enhanced MAX FRANK Shearail® on increasing the shear load capacity

Here we study the effect of (kmax= 2.5) on the maximum shear force.

In this example, the slab thickness, column size and all other parameters are the same as 'Section a'.

However, the design limit of Kmax vRd,c =2 vRd,c is not applicable for the well-anchored MAX FRANK Shearail® punching shear reinforcement system as a higher value of Kmax vRd,c =2.5 vRd,c can be achieved (kmax= 2.5).

The calculation (see Appendix 2) exhibits the maximum design value of the applied shear force (VEd) = 1166kN

MAX FRANK enhanced Shearail® outperforms all competitor products by 125% in the term of maximum shear force (VEd). This enhancement means that 25% extra shear force can be applied on the slabs - with no extra costs!

Section c) Application of enhanced MAX FRANK Shearail® on the reduction of the slab thickness

In this example we study the effect of (kmax= 2.5) on the thickness of the slab, while all other parameters are the same as 'Section a'. Therefore, the minimum thickness of the slab for the shear force (VEd) of 933kN, obtained in 'Section a' will be calculated.

The calculation (see Appendix 3) reveals that the slab thickness can be reduced by 40mm.

The reduction of slab thickness can save 15% on the concrete material and casting workmanship. It is interesting to observe that the slimmer slab reduces the total weight of the structure and results in smaller load bearing RC members i.e. RC columns, RC beams, RC foundations. As an example, for the above building, reducing the thickness of the slab by just 40mm will reduce the weight of the overall structure by more than 330 tonnes (see below).

The reduction of weight of the structure can significantly reduce construction costs.

6 floor x 550m x 0.04 x 25kN/m3= 3300kN, 330 tonnes or 132m3 saving!

Section d) Application of enhanced MAX FRANK Shearail® on the reduction of column dimensions

In this example we study the effect of (kmax= 2.5) on the dimensions of the columns while all other parameters are the same as 'Section a'. Therefore the minimum dimensions of columns for the shear force (VEd) of 933kN , obtained in 'Section a' will be calculated.

The calculation (see Appendix 4) exhibits that the column dimensions can be reduced by 210mm x 210mm.

The dimensions of the column can be reduced by 50%. The slimmer columns reduced the total weight of the structure, resulting in smaller RC beams, foundations. As an example, for the above building, reducing dimensions of columns to 210mm x 210mm will reduce the weight of the structure by more than 52 tonnes (see below). This reduction in the structure's weight can significantly reduce the overall construction costs.

6 floor x 25 columns No x 3m x (0.3m × 0.3m - 0.21m × 0.21m) x 25kN/m3= 516kN, 51.6 tonnes or 20.6m3 saving!

conclusion:

Considering the above examples it can be concluded that using enhanced MAX FRANK Shearail® can save the cost of construction in a number of ways:

- The maximum shear punching force can be improved results in 25% saving in shear rail costs (see Example 'Section b')

- The slab thickness can be reduced by 15% result in saving the cost of concrete material, casting and workmanship. In addition, the slim slabs can reduce the construction cost significantly by decreasing the weight of reinforced concrete structures results in a reduction of dimensions of all structural members i.e. columns and foundation.

- The dimensions of columns can be reduced by 50% result in saving the cost of concrete material, casting and workmanship. In addition, the slender columns can reduce the construction cost significantly by decreasing the weight of reinforced concrete structures results in a reduction of dimensions of all structural members i.e. foundation.

MAX FRANK Shearail® not only reduces construction costs, but also addresses the following:

- Reduce CO2 emissions - using less concrete

- Increase the construction speed and productivity - using less materials and labour

- Alleviate health and safety - reduced operations and labour

- Reduce the potential refurbishment and retrofitting of buildings - using less material for structural members

- Cut the risk of potential construction errors - reduced operations and labour

- Ease the design procedure - by providing more freedom for the Structural Engineers and Architects

- Addressed labour shortage - reduced operations and labour.

As the only punching shear solution approved by both BBA and CARES, Shearail® outperforms alternative products available on the market – at no extra cost.

Shearail® punching shear reinforcement not only fulfils the highest standards, but it is also fully supported by advanced and user-friendly design software and onsite installation support when required.

* The maximum factor that can be achieved by the application of shear reinforcement [NA-BS EN 1992, 6.4.5 (1)]

Shearail® - break the limits!

Another problem solved by MAX FRANK.

We recommend

+44 1782 598 041

Max Frank Ltd.

Clough Street, Hanley

Stoke-on-Trent, ST1 4AF

Staffordshire

United Kingdom