United Kingdom: english

United Kingdom: english International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Italy: italiano

Italy: italiano Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska Switzerland: deutsch

Switzerland: deutsch UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishHow to: Surface sealing of bored pile walls

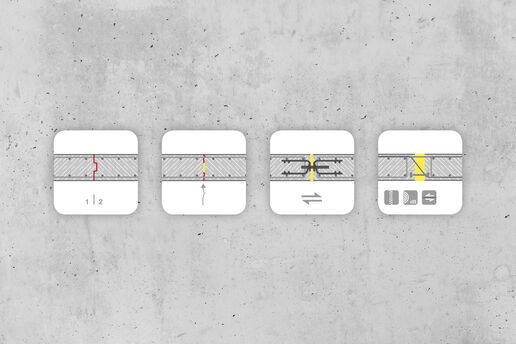

When sealing the surface of bored concrete piles, a flat surface is required, which can be achieved with the installation of the Pecafil® permanent formwork.

Separate layers, in front of bored pile formworks, are recommended for concrete saving and possible fine adjustment of basement walls in contrast to less accurate bored piles.

The sub-structure waterproofing system Zemseal® is applied where high-grade surface sealing is required - offering complete protection against moisture ingress. Zemseal® is applied to the flat layer of the Pecafil®, eliminating the need for subsequent crack injection - especially in concreted areas where access is limited or difficult.

How to:

- Apply the Pecafil® sheets to the bored pile wall and secure with a nail gun or by using dowels.

- Pre-fold the Zemseal® membrane for corner installation later on. After concreting the base slab, the Zemseal® sheeting should protrude approx. 500 mm upwards for easier connection.

- Position the prepared Zemseal® corner profile, followed by the surface sealing for the floor, on the blinding layer.

- Concrete the floor slab. Ensure that Fradiflex® metal water stop is installed in the construction joint between the floor slab and the wall.

- Attach pre-cut Zemseal® sheets in strips with Zemseal® adhesive tape (50 mm). Gluing with vertical strips can be done at intervals of approx. 1000 mm (gluing on the protruding wire of the Pecafil® mats).

- Reinforce wall, position wall formwork and concrete wall.

We recommend

+44 1782 598 041

Max Frank Ltd.

Clough Street, Hanley

Stoke-on-Trent, ST1 4AF

Staffordshire

United Kingdom