UAE: english

UAE: englishInternational: english International: englishAustralia: english

International: englishAustralia: english Australia: englishAustria: deutsch

Australia: englishAustria: deutsch Austria: deutschCanada: english

Austria: deutschCanada: english Canada: englishCzechia: český

Canada: englishCzechia: český Czechia: českýDenmark: dansk

Czechia: českýDenmark: dansk Denmark: danskFinland: suomi

Denmark: danskFinland: suomi Finland: suomiFrance: français

Finland: suomiFrance: français France: françaisGermany: deutsch

France: françaisGermany: deutsch Germany: deutschHungary: magyar

Germany: deutschHungary: magyar Hungary: magyarItaly: italiano

Hungary: magyarItaly: italiano Italy: italianoNetherlands: nederlands

Italy: italianoNetherlands: nederlands Netherlands: nederlandsNorge: norsk

Netherlands: nederlandsNorge: norsk Norge: norskPoland: polski

Norge: norskPoland: polski Poland: polskiRomania: românesc

Poland: polskiRomania: românesc Romania: românescSlovakia: slovenčina

Romania: românescSlovakia: slovenčina Slovakia: slovenčinaSpain: español

Slovakia: slovenčinaSpain: español Spain: españolSweden: svenska

Spain: españolSweden: svenska Sweden: svenskaSwitzerland: deutschUAE: english

Sweden: svenskaSwitzerland: deutschUAE: english UAE: englishUnited Kingdom: english

UAE: englishUnited Kingdom: english United Kingdom: englishUSA: english

United Kingdom: englishUSA: english USA: english

USA: english

International: english

International: english Australia: english

Australia: english Austria: deutsch

Austria: deutsch Canada: english

Canada: english Czechia: český

Czechia: český Denmark: dansk

Denmark: dansk Finland: suomi

Finland: suomi France: français

France: français Germany: deutsch

Germany: deutsch Hungary: magyar

Hungary: magyar Italy: italiano

Italy: italiano Netherlands: nederlands

Netherlands: nederlands Norge: norsk

Norge: norsk Poland: polski

Poland: polski Romania: românesc

Romania: românesc Slovakia: slovenčina

Slovakia: slovenčina Spain: español

Spain: español Sweden: svenska

Sweden: svenska UAE: english

UAE: english United Kingdom: english

United Kingdom: english USA: english

USA: englishHow to: Shear force transmission for load-bearing exposed precast concrete façades

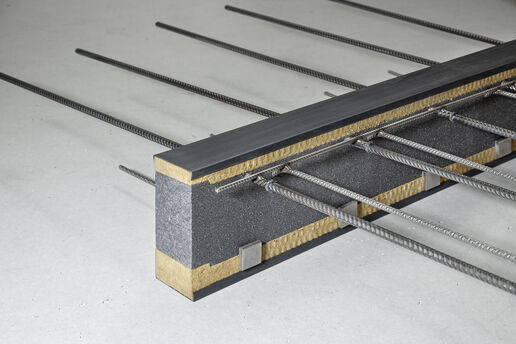

Design of the precast façade sections with insitu Egcobox® units, © www.maxfrank.com

For optimum shear force transmission, load-bearing precast concrete sections can be connected to the internal structure using Egcobox® thermal breaks.

A reduction in thermal bridging is achieved by thermally isolating the façade components from the internal structure using the Egcobox® connecting elements. In addition, optimum shear force transmission can be secured with the statically effective Egcobox® isolating element. For a cost-effective solution, Egcobox® units can be manufactured to suit structural requirements of this type of application.

How to:

- Development of the Egcobox® cantilever connectors as a bespoke solution for load and reinforcement layout.

- Production of the Egcobox® units for the precast plant.

- Assembly of the precast sections with corresponding preassembly of the Egcobox® units.

- On-site placement of the slab formwork for the in-situ concrete floor.

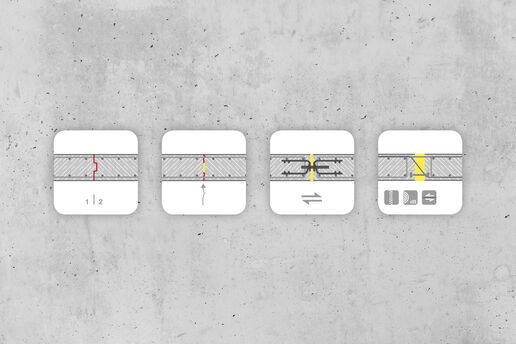

- To enable the façade panels to be installed after the frame has been cast, a recess can be created in the floor slab using Stremaform® shuttering to receive the Egcobox® reinforcement bars. Using the Stremaform® shuttering provides the characteristics of an 'indented joint' according to EC2.

- Mounting of the façade sections – securing the position with Egcodubel shear force dowel at the bottom of the elements and with the Egcobox® units placed into the recesses in the slab - which are subsequently concreted.

MAX FRANK provides static proofs and verifiable documents for special, customer-specific solutions.

We recommend

+971 6 5578197

Max Frank Middle East FZE

M3-15, P. O. Box: 123601

Saif Zone, Sharjah

United Arab Emirates